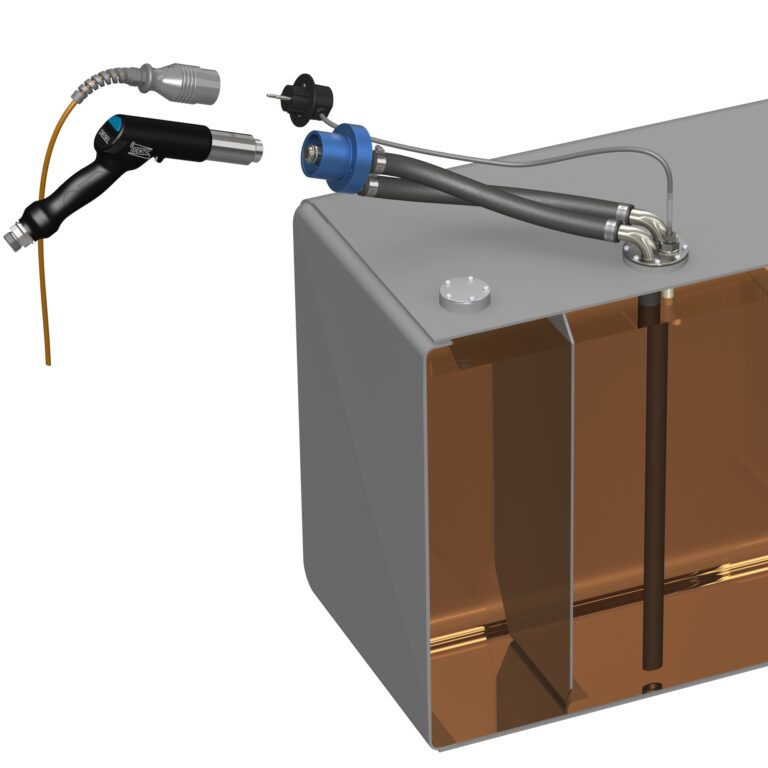

Environmentally friendly

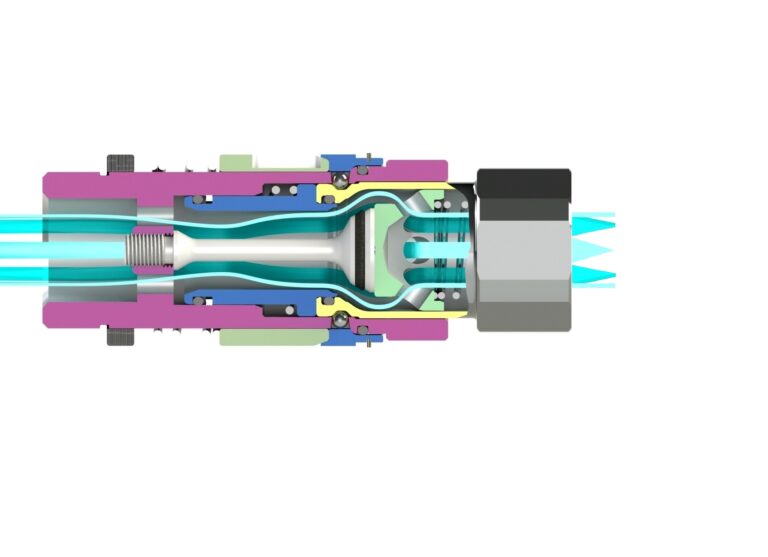

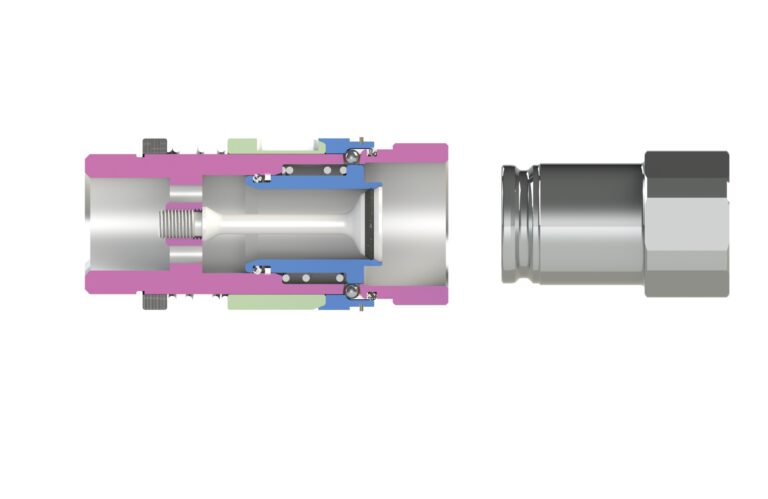

Regulations set high standards for safety in the workplace and environmental protection, so reducing the risks caused by spillage is an increasing focus area. The IDENTIC SVR system eliminates the risk of spillage before, during, and after the refuelling operation, which significantly reduces the risk of accidents and environmental damage.