What is an ATG?

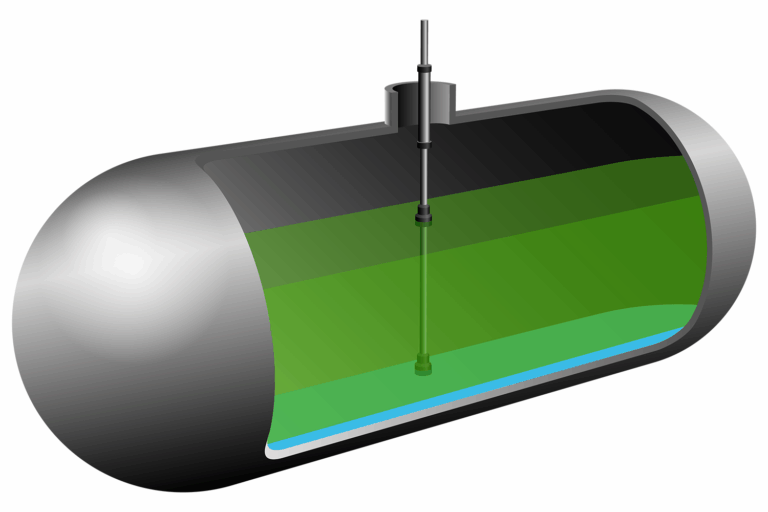

An Automatic Tank Gauge (ATG) is a sophisticated monitoring system used in fuel retail operations to track various parameters within storage tanks, whether they are underground or above ground. These systems are essential for detecting and measuring fuel levels, water levels, liquid temperature, volume and available space within the tanks.

Primarily utilised in petroleum and chemical storage tanks, ATGs ensure precise monitoring and reporting. They can issue alerts for high or low fuel levels and may include advanced features such as monitoring interstitial spaces, overseeing pressurised piping and enabling remote communication capabilities.

The ATG system comprises several key components:

Probe: Inserted into the tank, it measures the liquid level and temperature.

Console: Displays tank level information and calculates the volume of liquid in real time.

Communication System: Allows the console to transmit data to a remote location.

Some ATG systems are equipped with alarms and automatic shutdown features to prevent overfilling and other safety hazards. These systems are crucial for accurate and efficient stock management of liquid storage tanks, providing essential safety measures for handling flammable or hazardous liquids.

It’s worth noting that some devices only report stock levels and temperature without addressing compliance issues such as interstitial monitoring and sensor alarms, so it’s vital to choose wisely.

Importance of ATGs

Automatic Tank Gauges (ATGs) are indispensable tools for forecourt owners in the UK, offering a range of benefits that enhance operational efficiency, safety and regulatory compliance.

One of the primary advantages of ATGs is their ability to provide accurate and real-time measurements of fuel levels within storage tanks. This precision ensures that forecourt owners can manage their stock levels effectively, avoiding both stockouts and overstocking. By optimising fuel orders and reducing holding costs, ATGs contribute to improved overall operational efficiency. Additionally, accurate data supports demand forecasting and planning for future fuel deliveries, ensuring that the right amount of fuel is always in stock.

Leak detection is another critical function of ATGs. These systems continuously monitor storage tanks for any signs of leaks, which is crucial in preventing environmental contamination. Early detection helps mitigate the risk of soil and groundwater pollution, addressing issues before they escalate into significant problems. This proactive approach not only protects natural resources but also helps forecourt owners maintain compliance with environmental regulations, avoiding hefty financial penalties and reputational damage.

The automation features of ATGs significantly boost operational efficiency. By automating tasks such as measuring fuel levels, monitoring temperature and conducting leak tests, ATGs reduce the need for manual measurements. This automation saves time and labour costs, allowing staff to focus on other essential tasks. The real-time data provided by ATGs also enables quicker decision-making and more efficient management of fuel resources.

Regulatory compliance is a significant concern for fuel storage operations, and ATGs are essential in meeting these requirements. They provide precise and continuous monitoring of fuel levels and tank conditions, generating automated reports that can be used to demonstrate compliance with local and national regulations. These reports are crucial for audits and inspections, ensuring that forecourt owners can easily prove their adherence to safety and environmental standards.

Safety is paramount in fuel storage and handling, and ATGs are key to enhancing safety measures. By preventing overfilling and detecting leaks early, ATGs help avoid spills that pose fire hazards and environmental risks. Alerts for high or low fuel levels help to prevent such incidents, and early leak detection reduces the risk of accidents and ecological hazards, ensuring a safer working environment for both staff and customers.

In summary, ATGs offer forecourt owners in the UK a comprehensive solution for managing fuel storage efficiently and safely. By providing accurate stock management, early leak detection, operational efficiency, regulatory compliance and enhanced safety, ATGs are an invaluable asset in the fuel storage industry.

Key Factors to Consider When Choosing an ATG

Accuracy and Reliability: Opt for an ATG system that delivers precise and dependable measurements of fuel levels, water presence, temperature and leak detection. Verify the system’s industry reputation and track record for accuracy.

Regulatory Compliance: Verify that the ATG system is compliant with the regulatory requirements and standards in the UK. Compliance with environmental regulations and industry standards, such as EN 13160 for leak detection systems, ensures effective monitoring of fuel storage, leak detection and data reporting as required by authorities.

Compatibility: Ensure the ATG system is compatible with the site’s current infrastructure, including storage tank types and communication protocols. It should integrate seamlessly with the fuel management system and other relevant software.

Features and Functionality: Evaluate the features provided by the ATG system to ensure they meet operational requirements. Standard features include real-time monitoring, remote access, automated reporting, alarm notifications and integration with systems such as point-of-sale (POS) or fuel dispensers.

Scalability: Consider the future needs of the business and growth plans. Select an ATG system that can handle the current number of tanks and any future expansions. Scalability ensures the system can accommodate increased tank capacity or additional locations without significant upgrades.

Data Management and Reporting: Look for an ATG system with robust data management capabilities. It should store historical data, generate comprehensive reports and allow for easy analysis of fuel stock, usage patterns and leak detection. Customisable reporting options can help meet regulatory requirements and internal analysis.

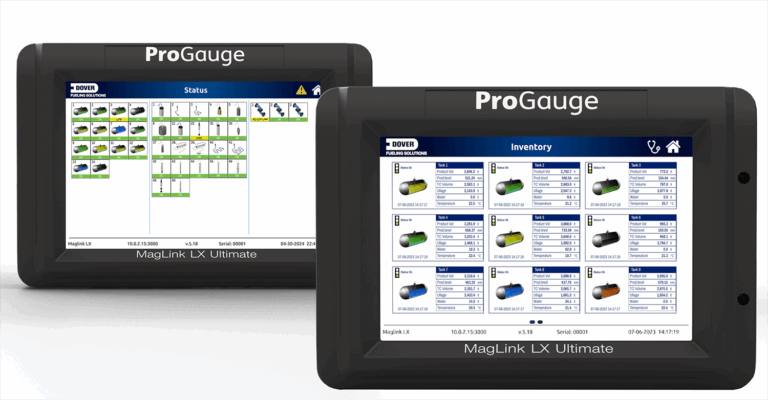

User Interface and Ease of Use: Assess the user interface of the ATG system. It should be intuitive, user-friendly and provide easy access to relevant data and functionalities. A clear and organised interface simplifies staff training and minimises errors.

Support and Maintenance: Assess the levels of support provided by the ATG system supplier. Ensure they offer dependable customer service, training and maintenance. Having a responsive support team is crucial for resolving technical issues and answering queries.

Cost and Return on Investment (ROI): Evaluate the total expenditure of the ATG system, including initial investment, installation and ongoing maintenance expenses. Assess the potential return on investment in terms of improved stock management, reduced fuel losses, regulatory compliance and operational efficiency. Compare upfront costs with long-term benefits to make an informed decision.

By taking these factors into account, forecourt owners can select an ATG system that meets their specific requirements, improves operational efficiency, ensures compliance with regulations and delivers a strong return on investment.

TSG is here to help

TSG UK is one of the leading providers of services and equipment in the industry, boasting over three decades of expertise in installation, maintenance and servicing. With a rich history of supporting a diverse range of clients, including independent networks, multinational oil corporations, supermarket chains and fleet operations throughout the UK, TSG has built a reputation for reliability and excellence. Its extensive experience ensures that it meets the unique needs of each client, delivering superior traditional and new energy solutions that adhere to the highest standards of quality and safety.

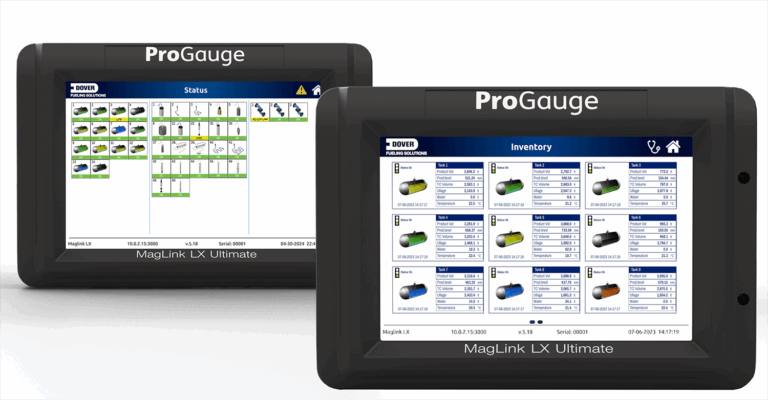

ProGauge MagLink LX® Console Family

TSG supplies the ProGauge MagLink LX® Console Family, a trusted name in ATG systems. This family comprises the MagLink LX Ultimate®, MagLink LX Plus® and MagLink LX 4® consoles. These consoles are designed to be environmentally friendly, seamlessly integrate with existing site cabling, maximise uptime and offer cost-effective solutions.

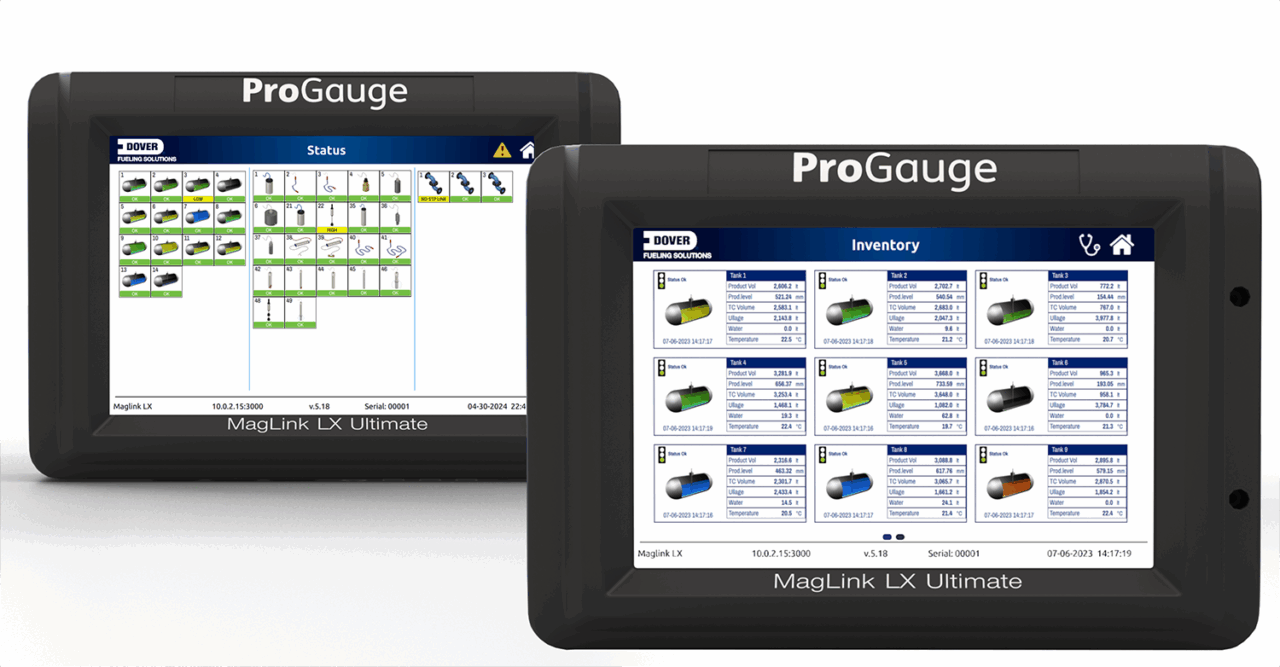

ProGauge MagLink LX Ultimate Console

The MagLink LX Ultimate console represents the next generation of tank gauge consoles. It is cost-effective, featuring patented multidrop technology to reduce installation costs. The user-friendly 12” display can show the status of up to 9 tanks simultaneously. Sustainability is a key feature, with Static Leak Detection (SLD) and Continuous Statistical Leak Detection (CSLD), as well as Electronic Pressurised Line Leak Detection (PLLD), included as standard. The MagLink LX Ultimate console seamlessly integrates with existing site cabling, offering flexibility and precision. It ensures high security with precise algorithms for 24/7 site monitoring and protection. Scalable to meet growing needs, this console can monitor up to 48 probes and 480 sensors across a fuel network. Additional features include automatic calibration and reconciliation, certified leak detection, support for wired and wireless probes, extensive reporting capabilities and programmable alarms.

ProGauge MagLink LX Plus Console

The MagLink LX Plus console features a vibrant 7” colour display with intuitive ‘touch and swipe’ technology, enhancing user interaction. Designed for scalability, it can monitor up to 12 probes and expand to include CSLD, PLLD and up to 48 sensors. Its advanced graphical display, brighter screen, faster processor and simplified reporting make it one of the most sophisticated tank gauge consoles. Additionally, its precise line leak detection system ensures continuous site protection, allowing leak tests on up to eight pressure lines via the console.

ProGauge MagLink LX 4 Console

The MagLink LX 4 console is designed for seamless interaction with its user-friendly touchscreen interface, featuring ‘touch and swipe’ navigation. It supports up to 16 probes, both wired and wireless, and can monitor manifolded or grouped tanks. The console provides automatic calibration and reconciliation, displaying comprehensive tank data, including volume, ullage, water level and temperature. It provides automatic leak detection and offers local or remote PC connections. Configurable through a web interface, it includes audio, visual, email and printed alarm notifications.

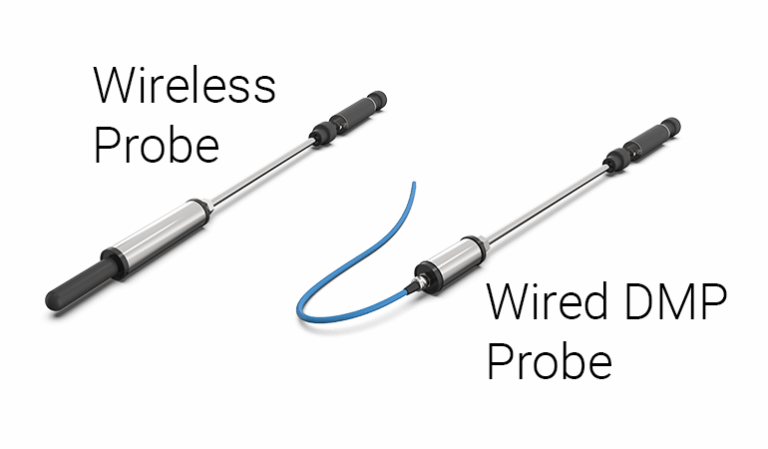

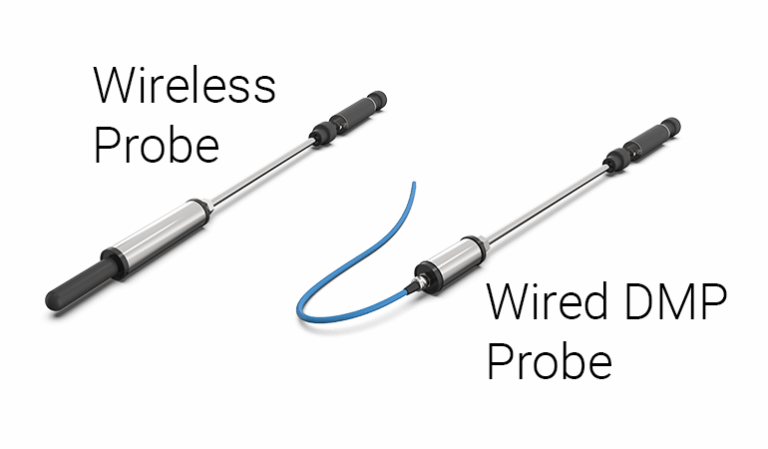

Probes

ProGauge probes monitor various fuel types and additives, including biofuels and AdBlue®. They support density measurement, phase separation detection, leak detection and fuel stock management. Utilising magnetostrictive technology, the probes emit a high-frequency electrical impulse that provides exceptionally accurate fuel readings, transmitted to the console on site or directly to the POS, ensuring rapid and dependable data transmission, early identification of water contamination and compatibility with all site types.

Author: Cheryl Ashton